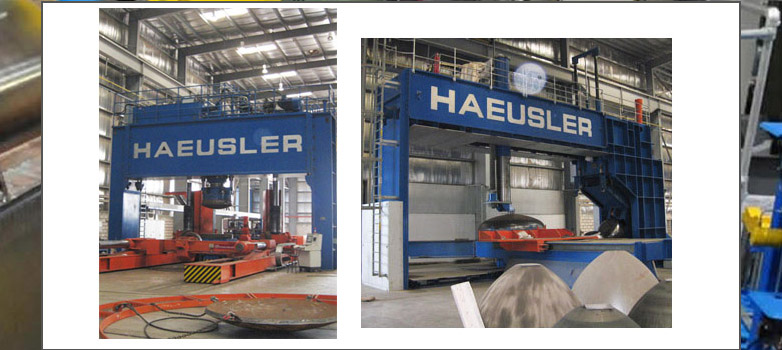

Dishing Press/Flanging Machine

For the production of dished ends and vessels HAEUSLER offers HKP dishing presses and flanging machines HBM in all sizes. On the HKP, the dished ends are pressed between 2 dies and thus formed. Since the size of the replaceable dies is limited, the forming process consists of repeating the pressing action with an intermediate displacement of the plate. This displacement is driven by the work piece manipulator. After pressing is done the flanging machine HBM rolls the plate’s edge into it’s final shape. Sheet thicknesses of more than 45-50 mm have to be machined hot due to the high degree of material deformation. The work-pieces opening is always pointing down which ensures slower cooling while processing hot materials. Therefore less re-heating is required compared to some competitor products.

Application

Application of our machines includes the following industries like, Wind mill, Ship building, Paper industry ,Boilers, Steel construction, Aero space Industry, Power plant ,Tank construction, Automotive Industry, Automotive Industry and railways.